Machinery Diagnostic Services:

DyRoMa LLC solves customers’ machinery

vibration problems with expert advice based on

sound engineering principles, knowledge of

modern rotor dynamics, and practical

experience. Our Machinery Diagnostics

Services (MDS) personnel are recognized as a

trusted source of deep knowledge on

machinery vibration behavior. Customized diagnostic

service programs are offered based on your

needs.

DyRoMa offers customer solutions in the following areas:

- Machinery vibration malfunction diagnostics for critical turbomachinery units and BOP

- Field and Shop Balancing (onsite balancing, trim balancing)

- Siemens Westinghouse 501 (W501) and 251 (W251) turbine generator units (501D5A, 501F…)

- Mitsubishi M501 (M501F, M501G…) and M701 turbine generator units

- GE Frame 7 and 5 turbine generator units (7FA, 7EA…)

- Siemens Westinghouse, General Electric, Mitsubishi, Toshiba, and other steam turbine units.

- Other turbomachinery units (compressors, pumps, gearsets…)

- Large industrial fans

- Machinery startup and turnaround assistance

- Shop acceptance testing

- On-site data collection and evaluation

- Machinery vibration diagnostic training

- Rotor dynamic modeling and consultation

- Second opinion for customer vibration issues

Second Opinion:

DyRoMa is very proud of our reputation that has been built over more

than 30 years for offering unbiased diagnostic assistance regardless of the equipment manufacturer. We will always “call it as we see it” no matter who manufactured, installed, maintained, or operates your machine.

Please contact us to discuss your needs.

Past Projects

Sample of Common Vibration Diagnostic Data Plot Formats:

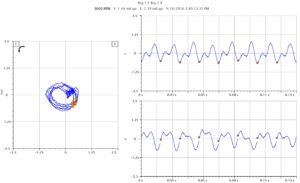

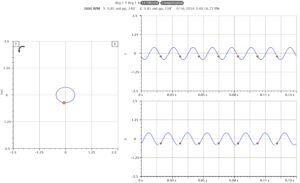

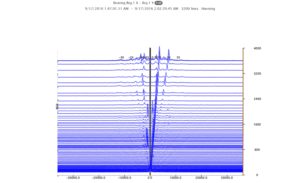

Orbit Timebase Plots, Direct (unfiltered) & Synchronously Filtered

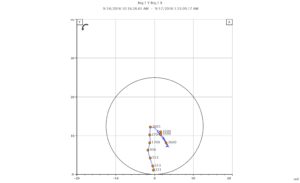

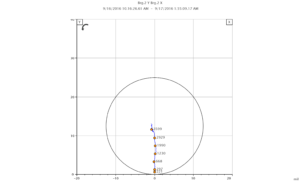

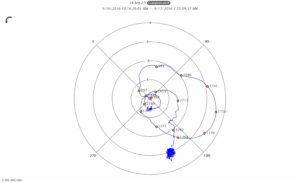

Shaft Centerline Plots

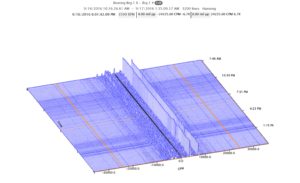

Waterfall & Cascade Plots

Bode and Polar Plots

A recent discussion concerning fluid film instability involving tilt pad bearings reminded me of another instance of whirl involving a tilt pad bearing from 2015, however the bearing was not the root cause. During startup of a 188MW DFLP turbine, vibration trip event at approximately 13:27 due to high vibration levels at LP bearings #3/#4. This startup was 3600 rpm and no load run of the unit. This event was caused by a sub-synchronous vibration condition (whirl), or called fluid film instability. Initial symptoms of this vibration occurred at about 13:18, and persisted at a low level for several minutes. This whirl condition had a frequency of 1370 cpm or 38% of running speed. For these whirl events, potential root causes were likely caused by either low gland steam seal vacuum, or bearing lube oil issue. Subsequent runs of this unit while under load exhibited no symptoms of whirl; bearing lube oil re-circulation was ruled out as a root cause. Both bearing #3 and #4 exhibited whirl of high intensity, which suggested gland steam vacuum was likely the primary root cause.